Magnetic Separation & Metal Detection

Cleaning Systems

Multiple combinations of magnetic and electronic separators can be used to meet your specific requirements. Cleaning Systems are designed for maximum protection against ferrous and nonferrous debris by combining magnetic and electronic separators. They are the perfect solution for purifying regrind and recycled goods in a plastics plant. Cleaning systems use magnetic and electronic separators to remove both ferrous and nonferrous contaminants efficiently from free-flowing virgin resins, regrind, and recycled plastics.

Magnetic Rotary Feeder

Magnetic Rotary Feeders are designed to meter the flow of products into processing equipment. It provides a continuous uniform flow of products to increase processing machinery productivity. The feed inlet has a spring loaded control gate which allows large metal objects to pass through the feeder without causing damage. Our magnetic rotary feeders sizes are up to 14-row with their specifications to meet your needs.

Gravity Magnetic Separation

Gravity Magnetic Separation provides continuous removal of ferrous contaminants from product flow. Enge Plas supplies various types of magnetic-gravity separators designed by our team of experts to access your needs and ensure you receive the right requirement for your applications.

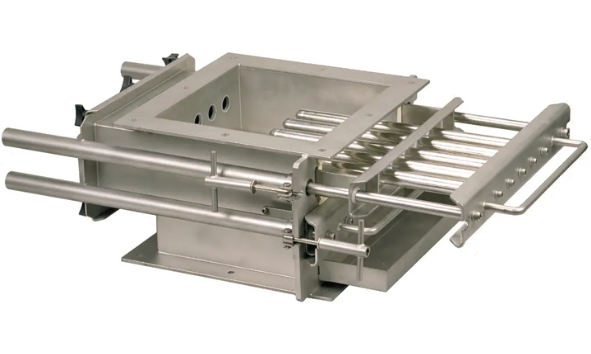

Pneumatic Magnetic Separation

Pneumatic magnetic separation helps balance between efficiency, operation and purity of products. They maintain continuous flow through the housing with no reduction in product velocity. They are easy to install into existing conveying lines and also compact spaces. Manual quick-clean and automated self-clean designs allow for easy cleaning. Above all, pneumatic magnets are effective in removing inbound contaminants in product streams. Pneumatic magnets are applicable in horizontal or vertical processing transfer lines. They are usable in gravity-fed chutes and dilute phase pneumatic conveying systems. Typical applications include powder or granular food products, pharmaceuticals, plastics, and chemicals. Enge Plas supplies a wide range of pneumatic magnetic separation technologies. This includes pneumatic tube magnet and line magnet. We also provide inline magnetic tube, plate magnet and pneumatic drawer magnet. Custom options include magnet tube lengths and single/dual magnet designs. Other equipment options include AAA sanitary welding, manual quick-clean or automated self-clean.

Liquid Magnetic Separators

Liquid Magnetic Separators remove ferrous contaminations from liquid and slurry product streams. It can be difficult flowing, fibrous or pureed products, or solid, thick and chunky slurry. They are applicable to chemical, food processing and paper milling industries. At Enge Plas, we help manufacturers control and remove metal contaminants. This helps achieve high food safety standards and minimize the risk of a product recall. We provide best practice know how and equipment to detect and remove metal contaminants. We provide a wide range of liquid magnets. This includes plate design, tube design (including high pressure),combo tube & screener design. Magnetic components used are from powerful Neodymium rare earth, ceramic magnet material. Our models come with quick release clamps to allow easy cleaning and inspection. They are easy to adapt and install to existing lines. Models can withstand temperatures as high as180°C and pressures as high as 150 PSI. Sanitary designs and USDA certifications (ASDA / AMS / NSF / ANSI / 3-A14159-1 2002) are available.

Magnetic Filtration Separators

Magnetic filtration allows for fluids to flow around the magnetic rod or core and capture any ferrous particles in magnetic trap. Our products and design help your manufacturing to reduce disposal costs, improve products accuracy and finish, and reduce machine and its part wear. Our magnetic technology is green and sustainability reduces both the need to buy costly consumables to help you save your cost.

Metal Detector

The most common and unwanted foreign material in production and processing is metal. Metal contaminants can cause severe damage to equipment, machinery and systems. And they may result in rejects, wastes and issues with customers. As such, metal detection is very important in protecting equipment and quality control. At Enge Plas, we supply a wide range of metal detection equipment. All types of metal and metal inclusions are detectable. Be it ferrous, non-ferrous and stainless metals, in conveying or gravity processes. Using powerful electronics and modern filtering, our devices apply in almost all applications. Our metal detectors sense and remove metallic contaminants with precision and reliability. Besides this, advanced engineering makes them long lasting and robust. Our range is applicable for conveyor belts, pipes, chutes, roll goods, bulk materials. Standard equipment include control units with touch-screen, networking capabilities for remote diagnostics. Useful options include wear resistance, high temperature, hygienic designs, multi frequency etc.

Magnetic Separation & Metal Detections Photo Gallery