Extruders & Others

Bulk Heat Exchangers

In many handling processes of bulk materials it is necessary to thermally treat powders or pellets, ie to cool or to heat them. The heat exchangers Enge Plas supplies is a high-efficient cost-saving apparatus, compact in design. For many industries, eg plastics, food, fertilizer or chemical, this offers an ideal solution for thermally treating the respective bulk materials.

Dust Collectors

The purity of bulk materials is a critical factor in the quality of the end product. Regardless of whether the focus is on minimizing product degeneration, cleaning products perfectly or determining the residual dust to comply with standards – Enge Plas solutions offer the optimal mix of many years of process competence and globally leading bulk materials expertise. Even at the design stage of the conveying plant, we ensure that dust generation will be minimized. For that reason, they select suitable pipe materials and flange connections and ensure conveying velocities to be in an acceptable range. The use of hydraulic conveying systems is providing best results to meet the highest quality requirements. We have a range of equipment which includes sieves and separators for efficient cleaning of the product from dust and streamers.

Mechanical Purging Agent

Enge Plas supplies a mechanical purging agent that enables the safe, effective and efficient cleaning of plastics processing equipment. This granular material is blended in with a small amount of the polymer that you are using and fed into a starved screw/barrel. The blended material is processed through your equipment at similar temperatures and revs to typical run conditions for the carrier polymer. The material softens slightly, but does not melt, and thoroughly loosens carbonized and degraded resin, allowing the polymer to flush out the system.

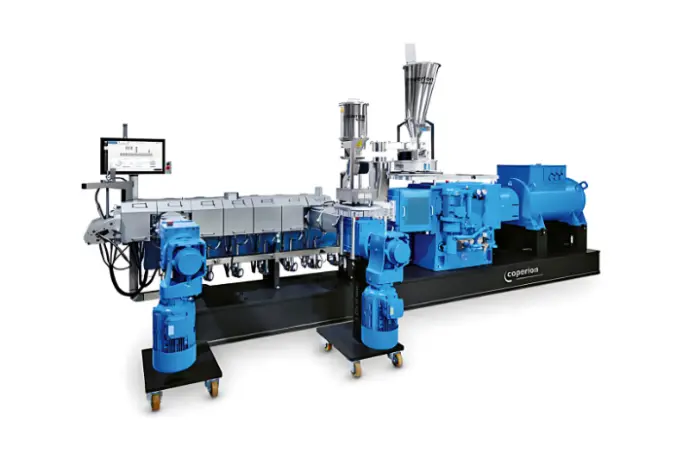

Extruders

Enge Plas provides total solutions for the processing technology from raw material feeding to the entire downstream periphery, from throughput rates of 1kg/h to 100 t/h. The quality quality of the end product is the decisive factor in complex processes such as the processing of viscous materials. From raw material through conveying, melting, dispersing, homogenising, devolatilisation, pressure build-up, filtering and pelletising, we use our experience and extensive know-how to adapt every process step exactly and we are able to guarantee maximum through put rates at the greatest possible economy and quality for our extrusion machines and plants.

Extruders & Others Photo Gallery