Weighing & Batching / Feeding & Dosing

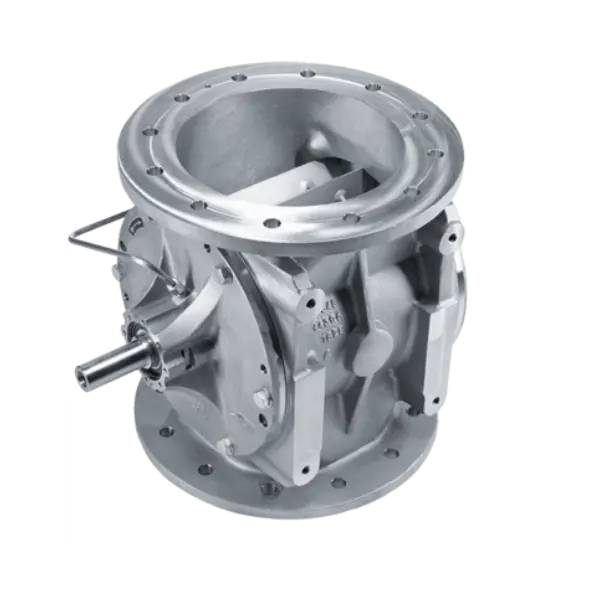

Rotary Valves

Rotary valves control product flow rate from silos and hoppers into conveying lines. They maintain a gas pressure differential between the inlet and outlet. And act as an explosion barrier, flame barrier and process isolator. Enge Plas supplies a variety of rotary valves for applications across different industries. From plastics to chemicals, food to minerals. The design of our rotary valves allows for quick and easy maintenance. Our rotary valves also set standards on high pressures and wear protection. Innovative technology allows best operational reliability and sanitary production. Options include sanitary and flameproof designs and ATEX conformity.

Rotary Valve Overview

Types of Rotary Valves: From left (Rotary Valve MD 1820, Rotary Valve ZFD, Rotary Valve ZRD, Rotary Valve ZRB )

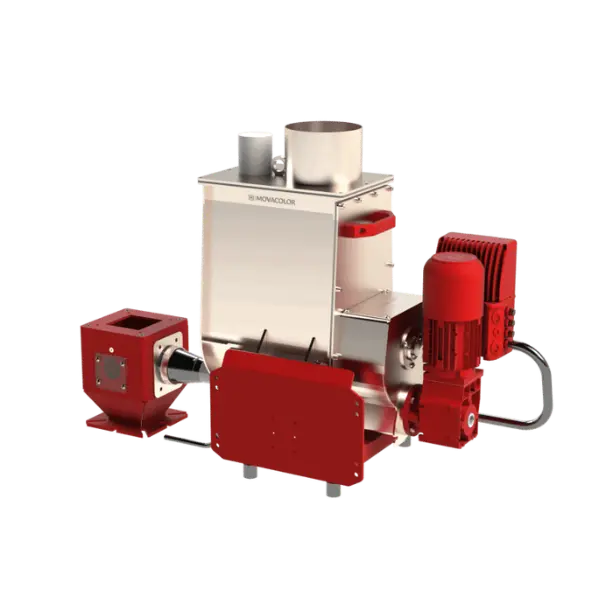

Feeders & Dosing Systems

At Enge Plas, we offer a widest range of dosing & feeding solutions. Our solutions are applicable in a wide variety of industries and applications. Applicable for batch or continuous, offline or online processes. No two process applications are the same, and feeding and dosing requirements vary. From chocolate chips to fiber glass, sticky powders, flakes, plastic regrind and waxy liquids. Different bulk solids flow behavior vary depending on material properties and particle geometry. Feeder design and sizing depend on the material characteristics and throughput requirements. Depending on application, our feeders and dosing equipment are volumetric, gravimetric or optometric. Designs vary from single to twin screw feeders, vibratory to weigh belts feeders. Or even bulk solids pumps, liquid feeders and flow meters. Finishing are standard or higher polish levels and ground welds for food applications. There are even special feeders developed for strict pharmaceutical hygiene requirements.

Dosing Systems Overview

Type of Dosing Systems: From left( MDS 25 HO Balance Powder NFF, MDS Balance Powder NFF)

Weighing & Batching / Feeding & Dosing Photo Gallery