Our Partner

Movacolor

Movacolor specializes in advanced dosing systems for precise color and additive control in the plastics industry. Their gravimetric and volumetric dosing technologies ensure consistent dosing of masterbatches, powders, and liquids. Commonly used in injection molding, extrusion, and blow molding, Movacolor’s systems guarantee high accuracy, minimal waste, and improved production quality. With user-friendly interfaces and modular designs, they cater to industries requiring precise dosing for color consistency and material optimization.

Main Product

MDS VOLUMETRIC FEEDER

A budget-friendly volumetric dosing solution equipped with a variety of options and functionalities for efficiently feeding plastic material into your production.

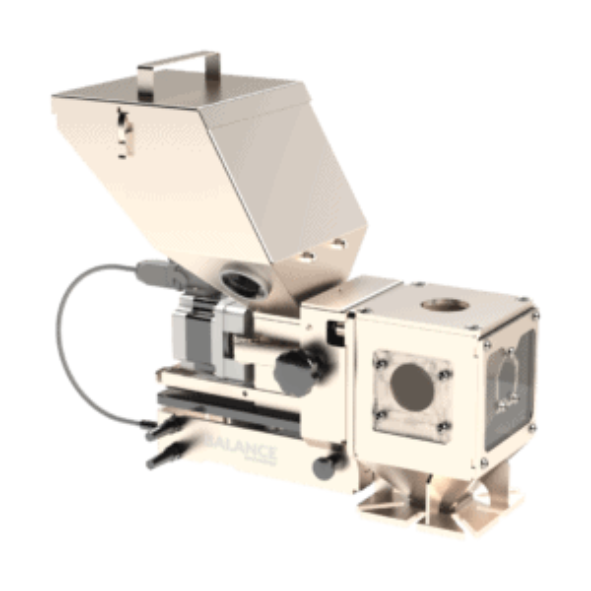

MDS BALANCE CLEANROOM

A gravimetric dosing solution designed to meet the stringent requirements of cleanroom environments, ensuring the highest standards of contamination control and material purity.

MBS BLENDER 20-EXTRUSION SERIES

A gravimetric blending solution with integrated continuous loss-in-weight technology to get the best out of your extrusion line.

Industry Application

MEDICAL

To eliminate variations, producers of medical plastic products demand high quality dosing machines for dosing masterbatch, powder, regrind and liquids. Movacolor equipment can be used in clean room applications as all contact parts are made of high grade stainless steel.

AUTOMOTIVE

For this purpose Movacolor have developed a wide range of dosing units which offer quality assurance and stable production in injection molding and extrusion. The dosing cylinder technique, in combination with well-designed controls and a stepper motor, guarantees accurate dosing in injection molding for automotive parts. This saves up to 50% on masterbatch, powder, regrind or liquids. And ensure the production of high quality end products.

WIRE & CABLE

Monitoring the extrusion production process of cables is getting more and more attention of plastics producers. The gravimetric loss-in-weight feeders offer the best monitoring possibilities. Connected to the LAN network, you can monitor all gravimetric dosing units in the factory by using just one computer. It is a perfect instrument to see what has happened during the night shift.

Components and Functionalities

GRANULAR

The MDS Balance by Movacolor ensures precise measurement in extrusion and injection molding, with the option to upgrade to a multi-component system for dosing up to six additives. For high-output processes, the MDS HO Balance offers capacities from 50 kg/h to 1,000 kg/h while maintaining accuracy. The MDS Nexus can dose as low as 0.1 kg/h, making it ideal for small granular capacities.

REGRIND

The MCS Regrind dosing unit, designed for regrind processing, uses two gravimetric MDS Balance units to adjust Masterbatch based on regrind levels. More regrind results in less Masterbatch, and vice versa. This accurate system significantly reduces Masterbatch costs and optimizes the use of rejects and waste.

FREE - FLOWING POWDER

Free-flowing materials can be dosed easily with Movacolor's gravimetric or volumetric feeders. The choice depends on whether you prefer a lower initial investment with a volumetric feeder or long-term savings with a more accurate gravimetric feeder. Gravimetric feeders utilize closed-loop, loss-in-weight technology for maximum efficiency in powder dosing. Both types feature a single or double spiral driven by a stepper motor, ensuring a consistent powder flow into the main material stream.