Our Partner

ISL Technologies

ISL Technologies Pte Ltd, specializing in solids handling through Intermediate Bulk Container (IBC) systems. Their IBC systems feature a distinctive cone valve, derived from the inventor of Cone Valve Technology in the United Kingdom, specifically designed for discharging and controlling challenging and cohesive powders. Collaborating with numerous partners and distributors worldwide, ISL Technologies caters to customers across Asia, Europe, and North America, offering tailored solutions for industries such as Food, Pharma, Chemicals, and others.

Main Products

INTEGRATED SYSTEM

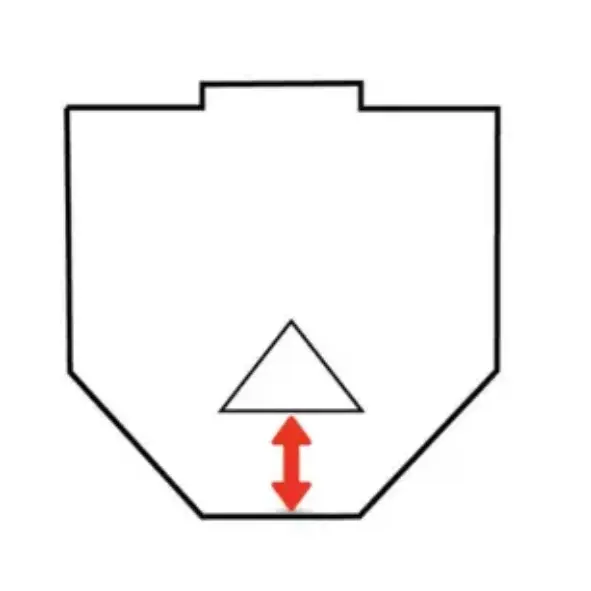

ISL’s Cone Valve has an integrated system that promotes and controls product flow

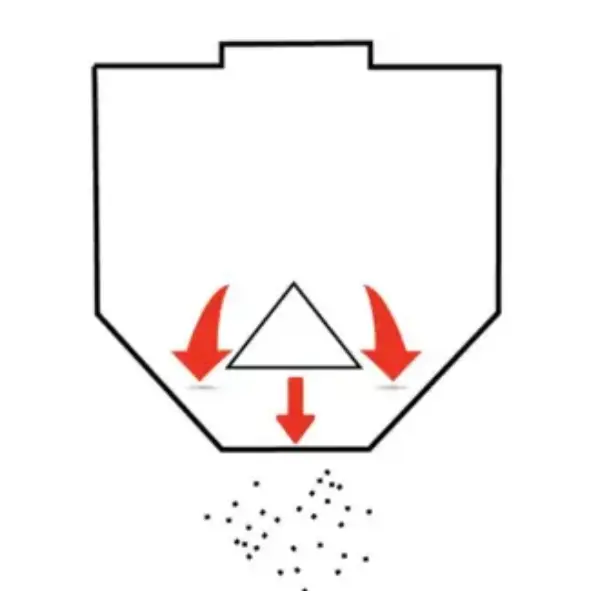

SYSTEMATIC DISCHARGE

When the Cone Valve is lifted for discharging the product or blended material, there is a systematic discharge of materials to avoid segregation

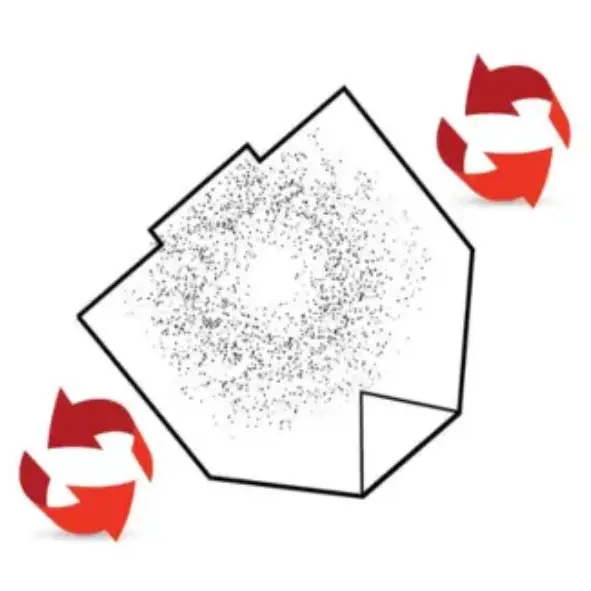

IN-BIN BLENDING

In-Bin Blending provides companies to blend the material in the IBC. Mixing directly within the IBCs reduces the number of product transfers by two (02) and the unique advantage of the cone valve is that during each revolution, it separates and re-mixes the product, so creating a better-quality mix

Industry Application

FOOD

ISL Technologies IBCs industry collection for the food sector highlights a comprehensive range of specialized solutions designed to enhance the efficiency and safety of food processing. The collection showcases a variety of valves and control systems tailored to meet the rigorous demands of the food industry. Key Offerings likely include sanitary valves and components that comply with stringent food safety standards, ensuring that the handling and storage of food products are both secure and hygienic. By focusing on the unique needs of different sectors—such as dairy, beverages, meat processing, and bakery, our conevalve demonstrates its commitment to providing industry-specific solutions that optimize operational performance and product integrity.

CHEMICAL

ISL Technologies IBCs offers an extensive range of specialized solutions tailored to meet the unique challenges of chemical processing and manufacturing. The Chemical industry is characterized by diverse applications and complex processes, where the handling of aggressive fluids and materials requires robust equipment designed for durability and reliability. ISL Technologies Ensure optimal flow management while withstanding harsh operating conditions. By focusing on the specific needs of chemical manufacturers, the company supports the development of efficient processes that enhance production capabilities and safety.

BATTERY

ISL Technologies IBCs are specifically designed to meet the stringent requirements of the battery industry, where the uniformity of powder blends is critical. These IBCs play a vital role in ensuring that battery powders maintain consistent homogeneity throughout the various stages of processing and discharge. Achieving this level of uniformity is essential, as even minor discrepancies in the composition of these blend scan lead to significant variations in the performance of the batteries. The engineering of these containers facilitates effective mixing and minimizes segregation, allowing manufacturers to produce high-quality battery materials that meet industry standards.