Our Partner

Hanwha

Hanwha Robotics specializes in providing Collaborative Robot solutions and actively engages in the development of advanced robots that integrate Hanwha's AI technology with mobility capabilities. Their Collaborative Robot (Cobot) offerings are versatile and can be applied to a wide range of processes, from simple tasks like pick & place and palletizing to more complex operations such as screwing, polishing, and dispensing. These solutions find applicability across various industries, including automotive, electronics, food, and pharmaceuticals.

Main Products

HCR-3A

Table-top cobot HCR-3A provides the optimal solution to whom needs the proximate co-worker. Easily installed and operated in internal area. It suitable for light-weight handling tasks of electronic industry such as inspection, screw driving and assembly.

HCR-5A

This is a perfect choice to collaborate with employees. For almost every industry and application, it improves working environment and let people concentrate on value-added work. It is suitable for pick & place, welding and inspection to increase productivity of manufacturing line.

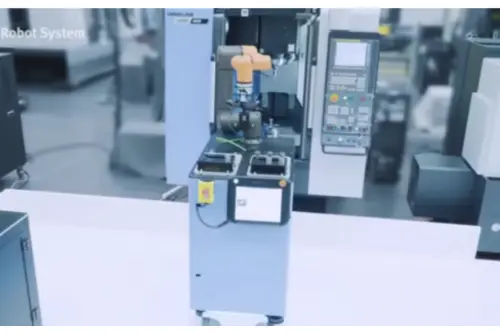

HCR-12A

This series has the widest working radius and a largest payload of all the entire series. It is most effective in automotive or metal processing industries, which deal with heavy and dangerous tasks such as loading & unloading metal materials. This cobot can make your working environment safer.

Industry Application

PALLETIZING

Automate palletizing and de-palletizing process of box type parcel. Does not require much space nor safety fence. Suitable for auto parts, food, timber, metal and furniture.

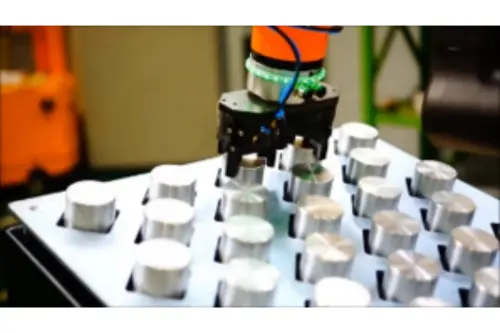

PART ASSEMBLY

For screwing and assembling components. System that can be configured with diverse tools to suit different assembly processes. Achieves high quality precise positioning and uniform strength in complex assemblies.

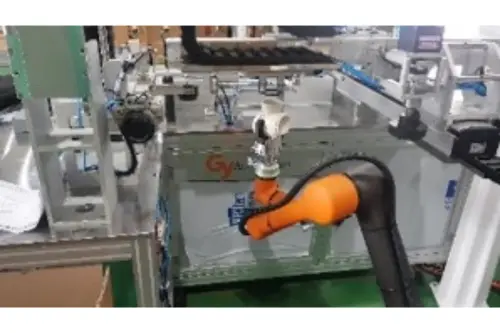

PICK & PLACE

Suitable for all industries. Easy programming and flexible set-up, maximizing productivity in the small-batch production system. The six joints of HCR can transfer and load products of diverse angles and positions.

Components and Functionalities

TEACH PENDANT (RODI - X)

HCR is easy to programming by HCR graphical user interface software. Timeline basis programming allows users to intuitively monitor the workflow. User grasps the robot and directly teaches the waypoint or the motion path to the robot.

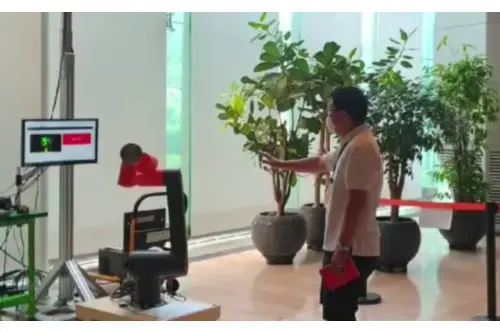

AUTO POSITION CALIBRATION

Using 2D image & QR code vision recognition. Suitable for intermittent production of limited items.

3D VISUAL SAFETY

Safe to install the robot right next to the operator as robot stops when it detects an external collision. Adopting two 2D camera to create safety zone.