Our Partner

Gneuss

Gneuss is renowned for its innovative solutions in plastics processing, specializing in filtration, measurement, and recycling technologies. Their patented Rotary Melt Filtration System offers continuous, self-cleaning filtration for extrusion processes. Gneuss also provides state-of-the-art MRS Extrusion Technology for efficient recycling of PET and other polymers without pre-drying. Widely used in packaging, automotive, and textiles industries, Gneuss systems ensure high-quality output, energy efficiency, and reliable performance in demanding production environments.

Main Products

MRS EXTRUSION CONCEPT

The unique MRS Extrusion System opens up entirely new avenues for the efficient degassing and extrusion of polymer melts. Furthermore, this system has outstanding dispersion performance for the introduction of gases and/or various types of additives.

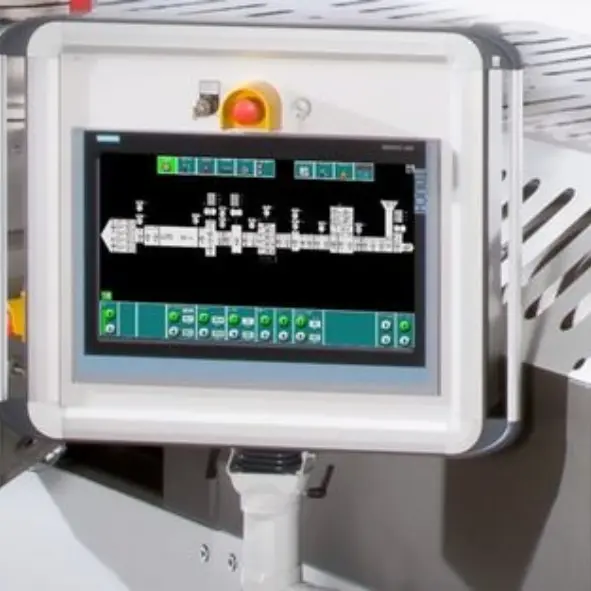

CONTROL TECHNOLOGY

The control system is an essential component of any extrusion line. Today, a control system is expected to connect all line components into an efficient and user-friendly central system.

VACUUM TECHNOLOGY

The vacuum system plays a key role in the devolatilization process. Not only is it important to create a vacuum — the separation of solid particles from the volatiles which are extracted from the melt presents a particular challenge.

Industry Application

SHEET LINES

Sheet extrusion lines based on the Gneuss Processing Unit (GPU) are used in the production of PET sheet for thermoforming all over the world. Sheet extrusion lines based on the Gneuss Processing Unit (GPU) are used in the production of PET sheet for thermoforming all over the world.

PELLETIZING LINES

With this concept, production waste from fiber, film and start-up lumps are placed into a shredder and are transported via a conveyor belt with metal separator into an intermediate container with an agitator. From there, the material is conveyed into the extruder by means of an auger and a crammer feeder.

FIBER & FILAMENTS

The demand for environment-friendly and economically sound production lines for synthetic fibers is increasing worldwide. The Extrusion System MRS fulfills both demands.

Components and Functionalities

RSFGENIUS SERIES

The RSFgenius provides unique possibilities in terms of achievable product quality, economic efficiency, and operator and maintenance friendliness. This fully autonomous and pressure-constant filtration system can be utilized in nearly any application for process automation and the manufacturing of high-quality end products.

POLYREACTOR JUMP

Within the JUMP reactor, the polymer passes across numerous slow turning components, forming a polymer film with a constantly refreshed surface. The reactor vessel is kept under vacuum, allowing ethylene glycol and other volatile chemicals to be evacuated reliably.

MELT PRESSURE TRANSDUCER WITH STANDARDIZED OUTPUT SIGNAL

The DA Series melt pressure transducers are utilized in the plastic production and processing sectors all over the world because of their excellent quality of craftsmanship and outstanding performance. Their extreme repeatability and consistent measuring values add to the accuracy of our measurements.