Our Partner

Fox Valve

Fox Valve specializes in manufacturing high-performance rotary valves and airlocks for bulk material handling systems, particularly in pneumatic conveying and dust collection applications. Their products, such as the Model 45 Rotary Valve and Rotary Airlock Valves, are designed to control material flow, maintain system pressure, and prevent contamination in industries like plastics, food, pharmaceuticals, chemicals, and mining. These solutions are known for their durability, precision, and efficiency in handling dry powders, granules, and other bulk materials.

Main Products

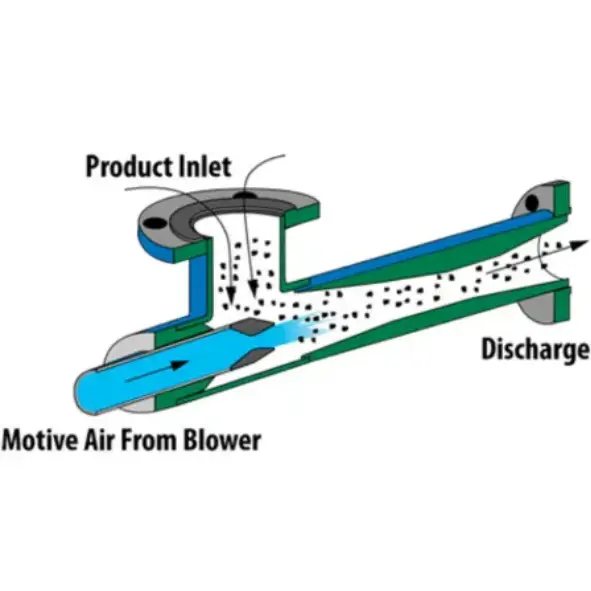

FOX SOLID CONVEYING EDUCTORS

Fox Valve has been the leading global supplier of venturi eductors and venturi transport systems for dilute phase pneumatic conveying of powders, pellets, and bulk solids since 1963. Fox Eductors, also referred to as jet pumps, enable the use of low pressure air to be used to move powders, pellets, and bulk solids with no moving parts.

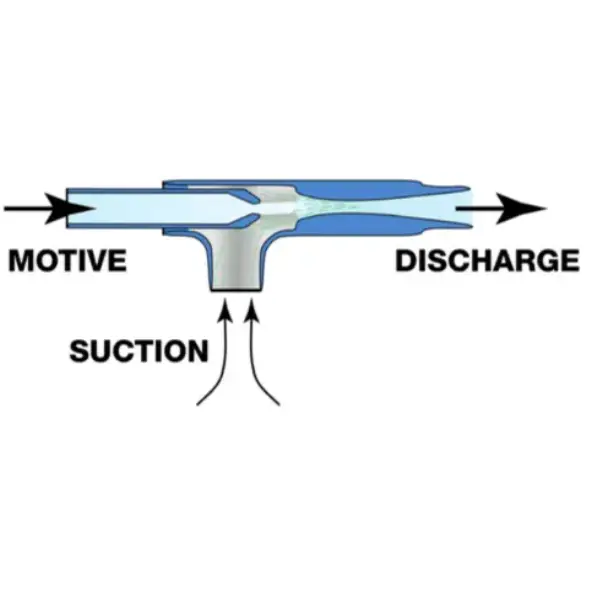

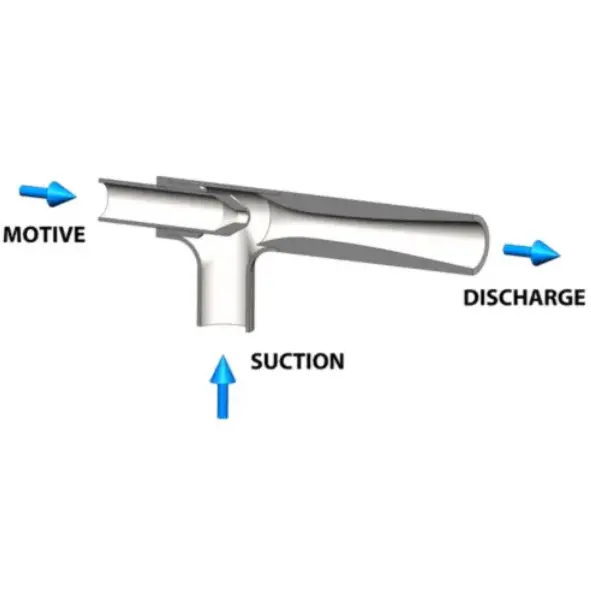

FOX AIR AND GAS JET EJECTORS FOR PUMPING GAS OR CREATING VACUUM

Fox Air and Gas Jet Ejectors are specialized devices designed for pumping gases or creating a vacuum using the Venturi effect. These ejectors operate without moving parts, relying on a high-velocity jet of air, steam, or gas as the motive fluid to entrain and compress the suction gas or create a vacuum.

FOX LIQUID EDUCTORS

Fox Liquid Eductors are venturi jet pumps that use liquid to create vacuum to mix, blend, or dilute other liquids, dry solids, or gasses into a liquid stream. They are used to replace or eliminate pumps when simple, ultra-reliable liquid mixing is required.

Industry Application

CEMENT INDUSTRY

Fox Eductors are used at Cement Plants in four major categories such as handling CKD, Cement, Limestone, etc Beneath Dust Collectors, injecting Waste and/or Alternative Fuels into Kilns, sorbent Injection & Hg Capture/Pollution Control, conveying Kiln Spill at up to 1500°F. With no moving parts, Fox Eductors are a forty year old solution to conveying abrasives like CKD, dust, and abrasive alternative fuels.

FOOD INDUSTRY

Fox Venturi Eductors have been in use at some of the largest pet food plants in the world, conveying kibble, kitty litter, and various pet food products with no moving parts, no dust, and no maintenance. One of the most common applications is use in packing rooms, where a Fox blower and eductor system is installed right in the packing area.

PLASTICS INDUSTRY

Fox Eductors have been used since 1963 to convey plastic pellets with no moving parts. Because Fox has been providing eductors to compounders for almost forty years, we have developed a line of eductors specifically designed for compounders. These offer easy-to-clean internals, product inlet ports custom-built to mate perfectly to your existing equipment, and the option of ceramic-liners if handling abrasive or filled pellets.

Components and Functionalities

FOX EJECTORS FOR METHANE CAPTURE

Global environmental organizations have identified methane – the primary constituent of natural gas – as a major contributor to global warming. Oil & gas wells, gas processing plants, and onshore and offshore drilling platforms and sites have been identified as possible sources of methane release via leaks and fugitive emissions.

FOX MINI-EDUCATORS

Fox Mini-Eductors are small venturi eductors that use pressurized gases or liquids to generate suction for a variety of sampling, pumping, mixing, or vacuum-generation applications. Fox stocks a broad range of off-the-shelf mini-eductors in 316 Stainless, Teflon, CPVC, Monel, Hastelloy, and Brass that can ship in just a few days.

VENTURI FLOWMETER

This Fox differential pressure venturi flowmeter includes AN ends for use with 37° flared tubing in an aerospace application. Any threaded end can be specified – such as NPT, BSP, AN, SAE. Fox can also weld on any commercially available tube or pipe fitting to facilitate installation in your process system.