Our Partner

Coperion

Coperion is a global leader in manufacturing twin-screw extruders, bulk material handling equipment, and complete compounding systems. Their advanced solutions, like the STS McPlus Twin Screw Compounder, excel in applications such as plastics production, chemical processing, and food extrusion. Coperion also specializes in pneumatic conveying, feeding, and weighing systems, ensuring precise and efficient material transport. With innovative technology and global support, they optimize processes for high-quality, sustainable industrial production.

Main Products

ZSK FOOD EXTRUDERS

The Coperion ZSK Mv PLUS twin screw extruder is designed for efficient food and pet food extrusion. Its modular design, high screw volume, speed, and torque ensure flexibility for various applications. With intermeshing, self-wiping screws, it eliminates stagnant zones, ensuring high efficiency and self-cleaning. Available in various sizes, it supports throughput from lab to production scale.

ZSK MEGAlab LABORATORY EXTRUDERS

The ZSK 18 MEGAlab laboratory twin screw extruder, based on proven ZSK technology, is designed for processing small batch sizes. It enables reliable scale-up to larger systems, making it ideal for formulation development and scientific research.

ZSK NT EXTRUDERS

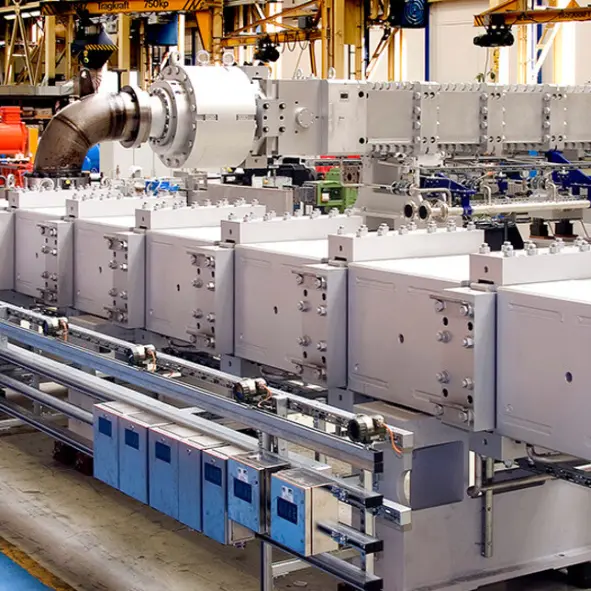

Bimodal polyethylene requires precise homogenization due to its wide molecular weight distribution. Long-chain molecules, key to product strength, must integrate seamlessly into the short-chain matrix, impacting workability. To address this, Coperion developed the ZSK NT, combining two ZSK MEGAcompounders for superior homogeneity and high-quality production, even for materials with broader molecular weight distributions.

Industry Application

CHEMICAL INDUSTRY

Producers of powder coating, adhesives, sealing compounds, toner, urea, laundry detergent etc. – numerous companies of the chemical industry rely on the first-class technology equipment of Coperion and Coperion K-Tron. We are longtime partners to the chemical industry and have comprehensive process engineering know-how.

PLASTICS INDUSTRY

We use our comprehensive system and process expertise to implement individual solutions for compounding and extrusion technology and bulk material handling for all plastics processing requirements.

MINERALS INDUSTRY

Our portolio encompasses pneumatic conveying systems, rotary and diverter valves, filters and special components which are used worldwide for numerous applications in the cement and ore processing industries as well as in power plants. Additional applications include the lime and construction industries as well as wood, ceramics and filler industries.

Components and Functionalities

VACUUM LOADERS

Coperion K-Tron vacuum loaders are designed to high quality standards for pneumatically conveying powders, pellets and granular materials for the bulk material handling industries. Our loaders are available in powder and pellet versions, as self-contained units or venturi style that utilized compressed air to create a vacuum convey source.

PELLETIZERS

Coperion has longtime experiences and extensive know-how in the production of pelletizers. We design our pelletizing systems to exactly meet the requirements of our compounding and extrusion lines.

STS MC¹¹ COMPOUNDER

The STS Mc11 series is exclusively equipped with European, Coperion branded gearboxes. Maximum screw speed has been increased from 800 to 900 min-1. To improve cleaning and facilitate quick changeovers for masterbatch applications, the STS twin screw extruder also features optimized hoppers with inserts and a redesigned die head.